3D Reverse Engineering Services

As more and more of the industrial world designs in 3D, the demand for 3D reverse engineering services has never been greater. 3D reverse engineering usually involves capturing the geometry of an object with a 3D measuring device and reconstructing it as a 3D model. This 3D model can then be used for a variety of tasks including design modifications, C.F.D, F.E.A, kinematic modeling, and various types of "proof of concept" design iterations.

The 3D scan data alone, however, lacks parametric qualities – so, in order for it to be utilized in a CAD program, it's necessary to have a parametric CAD model built over the 3D scan data using specialized reverse engineering software.

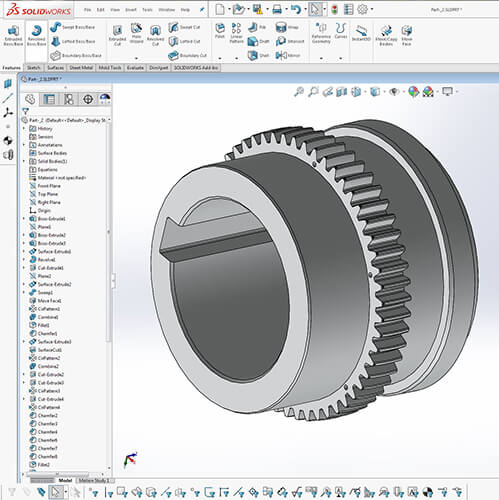

Scansite3D's standard CAD deliverable is STEP format. However, using Geomagic DesignX® software, Scansite3D can produce elegant and highly accurate CAD models for any of the mainstream CAD software packages including SOLIDWORKS®, CATIA®, Siemens NX®, Solid Edge, Autodesk Inventor®, PTC Creo® and Pro/ENGINEER®.

Some Typical Reverse Engineering Projects at Scansite3D….

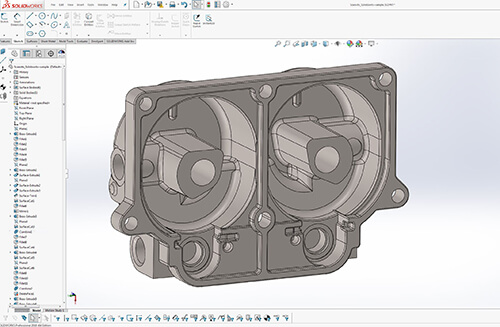

This marine carburetor part was scanned using a Breuckmann StereoScan® 3D scanner. The scan data was then reverse engineered using Geomagic DesignX® software.

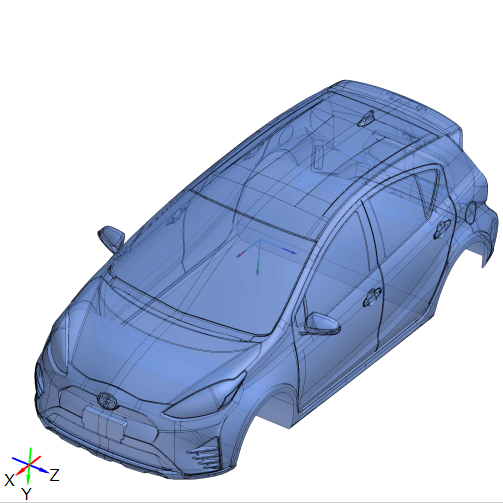

CAD model of Toyota Prius (Created from 3D scan data using Geomagic DesignX® software)

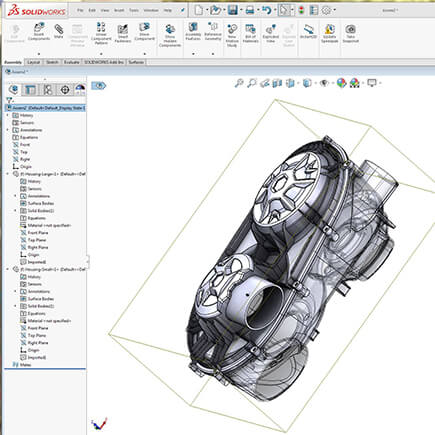

Solidworks® model of automotive transmission housing (Created from 3D scan data using Geomagic DesignX® software)

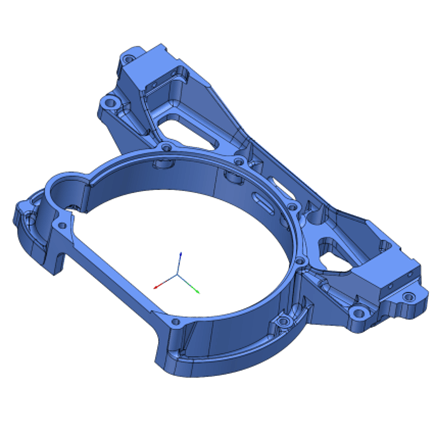

CAD model of automotive bell housing (Created from 3D scan data using Geomagic DesignX software)

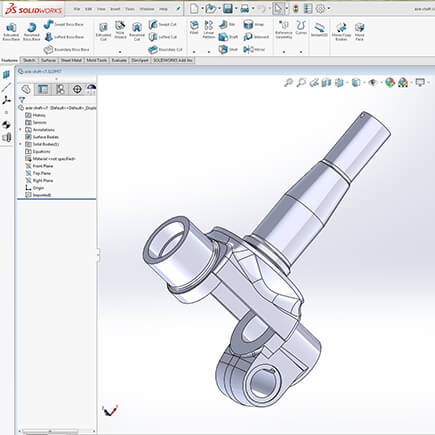

Solidworks® model of automotive front axle (Created from 3D scan data using Geomagic DesignX® software).

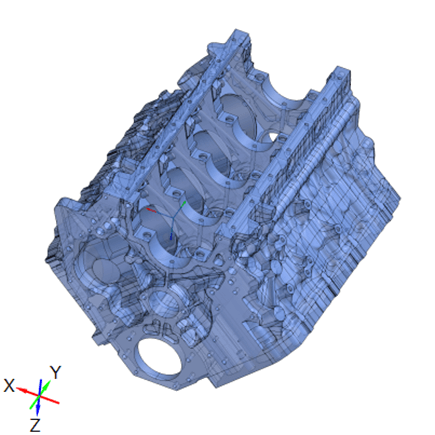

CAD model of Dodge Duramax V-8 truck deisel engine block (Created from 3D scan data using Geomagic DesignX® software)

Solidworks model of axle part for a San Francisco cable car (Created from 3D scan data using Geomagic DesignX® software).

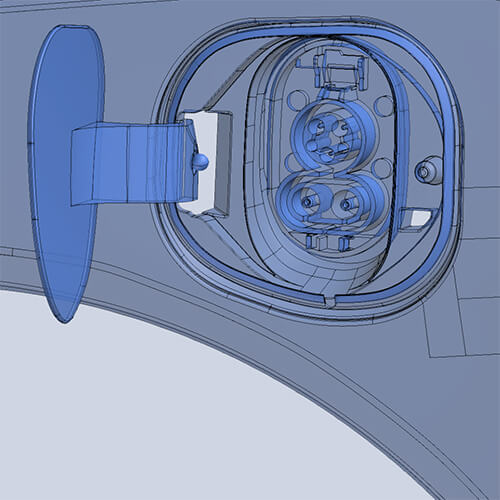

CAD model of electric car charging port created using 3D scanning. The file was created for downstream use in Solidworks using Geomagic DesignX® software.

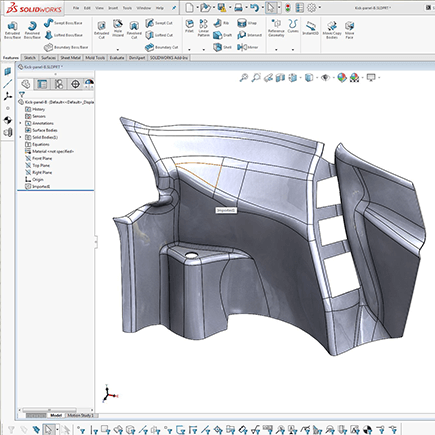

Solidworks model of Ferrari Scuderia 430 racing coupe interior panel (Created from 3D scan data using Geomagic DesignX® software)

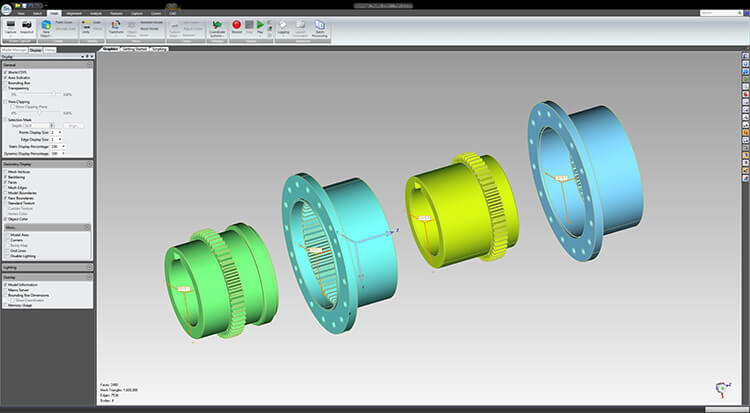

Creating CAD Assemblies for Solidworks

Most of Scansite3D's 3D reverse engineering projects involve single parts.

However, many CAD projects involve multiple parts that need to be designed in assemblies so that necessary relationships between components is maintained.

Scansite can deliver reverse engineered assemblies for software packages including SOLIDWORKS®, CATIA®, and PTC Creo®.

Not all 3D Scanners are Created Equal

Scansite3D has been reverse engineering 3D scan data in the bay area since the inception of the industry. Our hardware and software capabilities have remained top quality and our clients have grown accustomed to it, and we guarantee all of our files will import properly with no geometry problems. We know great reverse engineered files start with great data and that all scanners are not created equal.

Expertise Matters

Additionally, Scansite3D's engineers are constantly refining, advancing and perfecting their skills and we have demonstrated continually our ability to quickly grasp and understand our clients' needs. Whether the objective is to capture the original design intent, new product development, product visualization, or part replication, Scansite3D's reverse engineering services are dependable, repeatable and cost effective.