October 23, 2017

Author: Somerset Bassett

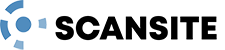

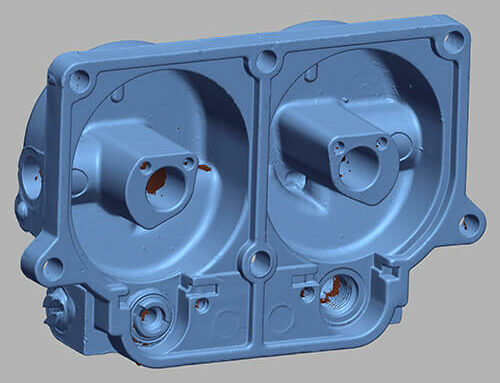

At Scansite3D, we have seen a marked increase in interest from legacy automobile owners. 3D scanning has fully captured the imagination of the classic car community and for good reason, too! It was 25 years ago that Scansite3D milled its first buck from scan data; and we still mill them, but now we also 3D print replacement parts and even redesign entire engines using the scan data as a starting point.

The growth of rapid prototyping technologies such as 3d printing and the ability to CNC parts in metal with high precision, have vaulted scanning technology to the forefront. Scansite3D has been creating extremely accurate scan data for some time, but now more than ever, machine shops and manufacturers have multiple options to utilize it. In other words, the industry is catching up!

The applications for using 3D scanning on classic cars are varied and growing rapidly. Uses include making replacement parts, repairing broken components or simply documenting the as-built condition of the automobile. And let’s not forget – buck making and sheet metal fabrication! Scanning and reverse engineering facilitates efficiency improvements, inspection, easier production, and even the ability to change materials to create lighter or stronger parts.

However; just like the restoration of a classic car, the success of a project rests entirely on the process and all scanners are NOT created equal. Reproducing a windshield, for instance, which matches the exact dimensions of an existing part, which was made by hand, can only happen if you start with a highly accurate 3D scan. Otherwise, errors that are inherent with inferior data will ‘stack’ and the results can be disastrous.

At Scansite3D, all our scanners are Aerospace certified and our engineers and support staff are the most experienced in the business. Spending time and money on a poor scan, and then manufacturing parts from it, can be a frustrating and expensive experience. Those who bring their engineering projects to Scansite3D, receive 25+ years of scanning and engineering know-how, as well as, the deep understanding of how to use the data once it goes out the door.